en

In the past 20 years, Gangye Valve has provided products required by different customers in various industries in strict accordance with industry standards (petroleum industry, chemical industry, energy power industry, natural gas industry). In terms of qualifications, Gangye Valve has the TS, A1, CE certification of China and the API certification of the United States. In terms of price, Gangye Valve has its own raw material suppliers, so it can provide customers with the best prices.

In terms of qualifications. Gangye Valve has TS, A1, CE, API certifications, and produces high-quality valves in strict accordance with industry requirements

In terms of resources. Gangye Valve has more than 760 employees, including 20 senior engineers, who can produce products efficiently

In terms of price. The raw materials Gangye Valve needs to produce products come from its own downstream companies, so it can effectively reduce costs and provide customers with the most suitable prices.

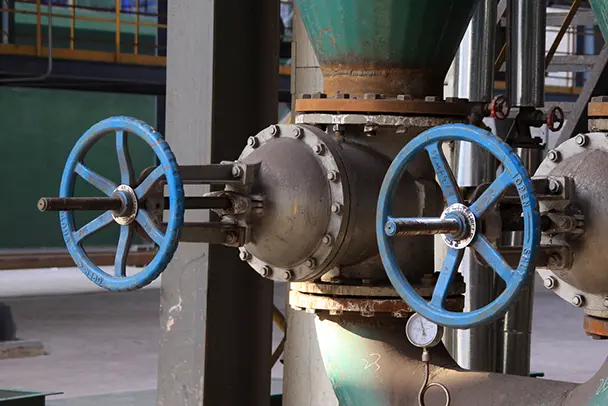

Industrial valves are used in pipelines of various systems in oil transportation, natural gas transmission, chemical plants and thermal power stations. The function of the valve is to cut off and connect the medium in the pipeline, and it can be applied to corrosive media (such as water and hydrochloric acid) and Non-corrosive media (distilled water and gasoline).

After the valve is installed on the pipeline, the staff can open or close the valve according to different valves. The check valve does not require manual operation. When gate valves, ball valves, globe valves and butterfly valves are not equipped with pneumatic or electric actuators (such valves are usually used in low-pressure environments), staff need to manually turn the handwheel to open or close. Pneumatic and electric Actuator valves (such valves are usually used in high-pressure environments), the staff can remotely operate pneumatic and electric actuators to open or close the valve.