en

The 10 check valve is an important flow control device used to prevent backflow in pipelines with a nominal pipe size (NPS) of 10 inches. When reverse flow occurs, it automatically shuts off, ensuring unidirectional flow and protecting pumps, compressors, and other critical equipment. 10 inch check valves are used in a wide range of applications including water treatment, oil and gas, chemical processing, power plants, and HVAC systems.

The 10 inch check valve is available in a variety of configurations, including swing-open, lift-open, butt-clamp, and double-valve. According to the installation requirements, it can be categorized into vertical and horizontal types, adapting to different working environments and application scenarios.

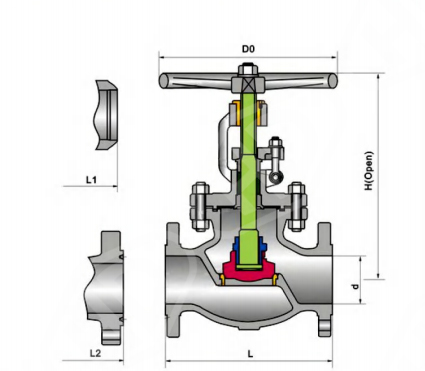

| ANSI Class 150lb | ANSI Class 300lb | ANSI Class 600lb | ANSI Class 900lb | |

| NPS | 10 | 10 | 10 | 10 |

| (RF/BW)L/L1 | 622 | 622 | 787 | 838 |

| (RTJ)L2 | 622 | 638 | 790 | 841 |

| (OPEN)H | 815 | 900 | 1140 | 1570 |

| d | 250 | 250 | 247 | 238 |

| Do | 400 | 500 | 600 | 600 |

Size & Compatibility: Designed for NPS 10 (10-inch) pipelines, suitable for industrial and commercial applications.

Material Options: Available in stainless steel, carbon steel, cast iron, CF3M, CF8M, and more, ensuring durability and corrosion resistance.

Connection Types: Offered in flanged (RF), butt-weld (BW), and threaded connections for versatile installation.

ANSI Pressure Ratings: Available in Class 150, 300, 600, 900, and higher, suitable for different pressure and temperature conditions.