en

The slab gate valve is the same as the ordinary gate valve. Their opening and closing actions are performed by operating the gate for linear motion. However, the slab gate valve has a flat closing element perpendicular to the fluid. This element makes the operation of the slab gate valve more flexible, so its use Lifespan is longer.

Oil and gas transportation pipelines

The medium in the transportation pipeline has suspended particles

Gas transportation pipeline

Urban water pipes

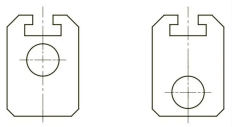

The deflector plate gate valve is one of the plate gate valves, which can be divided into normally open (figure left) and normally closed (figure right). The normally open guide hole is in the middle and upper part of the gate, and the normally closed guide hole is under the gate. Due to the existence of the guide hole, the resistance of the valve is smaller when it is opened and closed, so the torque is smaller when the valve is opened and closed. Deflector plate gate valves are suitable for transporting fluids containing solid particles or high viscosity because the deflector prevents excessive resistance caused by solid particles or high-viscosity fluids when the valve is opened and closed.

Durable Sealing: Special treatments and multiple seals ensure corrosion, penetration, and abrasion resistance, extending the valve's service life.

Efficient Full Bore Design: Minimizes flow resistance and pressure loss, providing optimal fluid flow with reduced erosion on sealing surfaces.

Flexible Installation and Maintenance: Allows both parallel and perpendicular installation and can be cleaned directly via pipeline cleaners.

Smooth Operation: The plate design minimizes friction during closure, ensuring smooth operation and a longer lifespan.

Versatile Application: Ideal for natural gas, chemical industries, and urban construction, with reliable flow adjustment and tight sealing.

Consider the Application:

Match the valve's pressure and temperature ratings to your system.

Ensure the valve material is compatible with the medium (e.g., water, oil, gas).

Select the Right Material:

Use carbon steel for high-pressure applications.

Use stainless steel for corrosive environments.

Choose the appropriate seat material for sealing performance (soft seals for tight shut-off, metal for high temperature).

Design and Flow:

Full bore valves allow full flow with minimal pressure drop.

Reduced bore valves are more compact but add some flow resistance.

Choose end connections (flanged, welded, threaded) based on your piping.

Operation:

Pick manual or automated (pneumatic, electric) actuation based on how often the valve will be used.

Standards:

Make sure the valve meets required certifications like API 600 and ISO 9001.